What happens to leftover medical supplies? Hospitals or clinics buy excess that they don't need, and still have extra after all prompts use up votes That can be a wonderful quality, yet one not without its perils, so we need to take it into account. So we now know the processes quite well, why some places store more supplies than they need it and how others give to those in need and what happens with these surplus items that could be trashed soon.

You have to know that there are hospitals[..]clinics who hoard more medical goods than they need? Such practice is hoarding. Hospitals do this so that they always have around where the material needs to go in an emergency, often resulting from something that nobody could predict. Stocking up is often seen as the smarter strategy, but it can actually be a way of throwing money down the drain and wasting space that could be used for other important items.

Storage — Excess supplies occupy much-needed storage in the meantime, increasing costs and pushing hospitals from putting away new equipment or other things. Moreover a number of site supplies could remain unused for long periods and end up expiring before they are need. Unuseful or obsolete supplies may also prove lethal to the patients, as they will not be work adequately and some may harm them.

When and if something does happen the last thing you want to do is spend time trying to get a certain kind of medical supplies, the more you have on hand though the better. To continue with the disease example, the faster and more resource hospitals and clinics have access to at-the-ready, they can provide a quicker and stronger response. For example, it could be critical in an emergency department where patients might need immediate intervention to be able to recuperate from injuries or life threatening disease

Hospitals and clinics are starting to see the benefits of having a surplus of medical supplies which can go towards other health care facilities for patients in need. Back in the hospitals they call that “medical overage.” All these patients were also provided medical care at public clinics or hospitals which not only fail to consume a large quantity of other high-quality equipment (such as endoscope), but the equipment is 10-20 percent consumed and stored well enough for blood donation.

The extra supplies are given to various kit collecting organizations and groups for use in sharing with those in need. For example, Konlida Med works with hospitals to take surplus supplies and put them in the new building. Not only does this reduce waste, but saves cash-strapped hospitals from having to purchase new equipment while other institutions are simply kicking these supplies out.

Remember, too — supplies donated should be safe. Sometimes they consider old dated or un serviceable which could be dangerous for the patients. Your safest bet is to partner with entities that follow rigorous guidelines for the disposition and procurement of medical surplus. Of course, safety and quality are essential for patient health overall, as the severity of illness or injury is greater in groups who are more likely to need these supplies.

Konlida Medical a high-tech company that integrates engineering medicine and clinical medicine is a high tech enterprise We provide affordable medical equipment that improve the quality of life and provide lifesaving treatments for patients Konlida Medical offers comprehensive customizations and constantly searching for needs from customers We provide product parameter optimization ideas dependent on the specific usage patterns of our customers This helps them enhance efficiency while medical supply surplus Our OEM/ODM service is available to meet the various demands of our customers' processing Our commitment to innovation and delivering solutions that are geared towards the needs of our customers ensures that we stay ahead in the medical field and deliver products that make a the difference in patients' lives

Konlida Medical has a research team comprised of experts in pharmacology clinical medicine as well as chemical engineering and mechanical manufacturing Our company employs over medical supply surplus and RD personnel We have also established close relationships with various hospitals and universities We own many independent intellectual properties and have several patents that are national in scope Konlida Medical offers regular academic and professional seminars and workshops with a focus on the advancement of the company and its staff This process enhances the education abilities of the company and aims to improve overall staff quality Our system of operation continuously assists the transfer of knowledge into practical applications This is the basis for improvement and innovation in the business

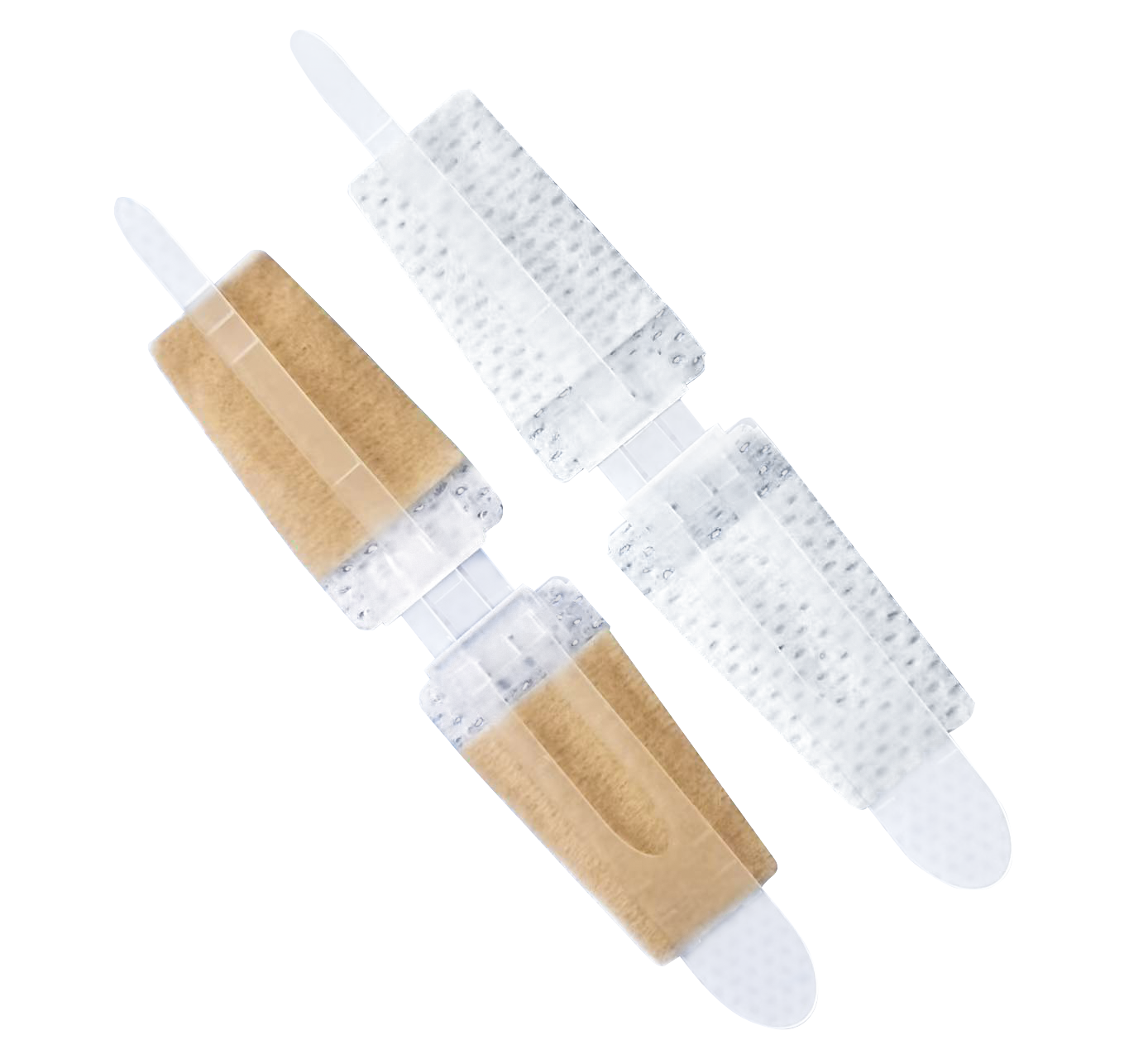

medical supply surplus the world changes as we age, the demand for beauty increases, which makes the need for surgical procedures and scar reduction one of the major areas of concern. The reduction of scarring and trauma for patients and enhancing the medical expertise of healthcare specialists and decreasing their workloads are a hot topic for ongoing research and development in the field of medicine. In this regard, Konlida Medical leverages its high-tech innovation capabilities as well as its adaptable manufacturing and production capabilities to develop specialized wound care products. By developing strong relationships with various universities, research institutions, as well as medical institutions, we focus on wound treatment and care to meet the healing and treatment requirements of different wounds. We're determined to provide new health benefits to patients and a brand new era in recovery and hope.

Our company has an Class 10, 000 medical supply surplus as well as a Class 100,000 cleanroom. We also have the Class 10,000 lab for biological research as well as a physical and chemical laboratory, as well as a storage and purification system for water that meet the needs for anaesthetic manufacturing. We have over 18 years of industry expertise, and we use advanced equipment for every stage of production. Konlida Medical is ISO13485 certified this means that every step that are performed, from inspection of materials and production control through to logistics storage and warehouse are carried out in line with the industry standard. This approach ensures that high-quality medical products are produced.

Copyright © Suzhou Konlida Medical Supplies Co., Ltd. All Rights Reserved Privacy Policy