Have you heard about hydrocolloid bandages? Adhesive bandages are special types of strips that are used to cover up cuts, scrapes or wounds so they heal quicker and do not let germs in. Today, in this article we will cover everything about Hydrocolloid bandaids, how do hydrocolloids work and the right way to use them for better healing of our wounds.

They create a moist environment, and are able to absorb more wound exudate than gauze dressings. This magic goop is called hydrocolloid, and it's made of ingredients like gelatin and pectin which are actually safe for our skin. A hydrocolloid bandage creates a homeostasis environment around the wound. A moist environment is good for the healing of wounds as it helps them to heal more rapidly than if they were dry.

Said that when you put on a hydrocolloid band- aid over top of an open wound, the moist environment it provides helps speed up healing time because cells can basically thrive. This is because the moisture ensures your cells are kept alive and on a mission to assist each other repairing damaged skin. It serves as a disinfectant and blood preventor from inflicting any infection. It is so critical because germs can lead to infections, and then healing will take much longer. A hydrocolloid bandage is actually doing you a big favor by protecting the wound and promoting healing.

Chronic Wounds: Chronic wounds are wounds that take a long time to heal. The pain and discomfort that chronic wounds bring can make it difficult for a person to get through their daily routine. Hydrocolloid bandages are good for this situation too, they will help take the pain out of that part and also make sure it does not get infected. If you have a wound that is taking its sweet time to heal, these fitted overtop and provided a piece of your own skin as cover so the healing could commence.

Hydrocolloid bandages have two categories i.e. sticky (glue/border) and non-sticky ones without any adhesive bond in them. Among occlusive or adhesive dressings, sticky hydrocolloid bandages are a layer to helps them attach securely over the wound. This is beneficial particularly when you have a wound at any moving body parts like arm or leg. Non-sticky hydrocolloid bandages are free from such adhesive layer, so they would need another dressing or tape to keep them in place. If the wound is on a non-mobile area, you may not need to use anything more viscous like an hydrocolloid.

Before slapping a hydrocolloid bandage on any wound, be sure it is clean and dry. This will help the bandage adhere to your skin correctly. A poorly sticking bandaid will likely not work as well. You should also make sure that the bandage goes on entirely covering the wound and not just around all tapery. This allows to maintain the dampness within as well as avoid dirt.

Hydrocolloid bandagesLastly, remember to slowly and gently REMOVE a hydrocolloid bandage if you need to. Even if gradual some people try to remove it at a fast and that is harmful because the damage or pain caused by the wound. Once you take off the bandage, clean and dry the wound before re-applying a new one. This will assist to maintain the area healthy and prepared for recovery.

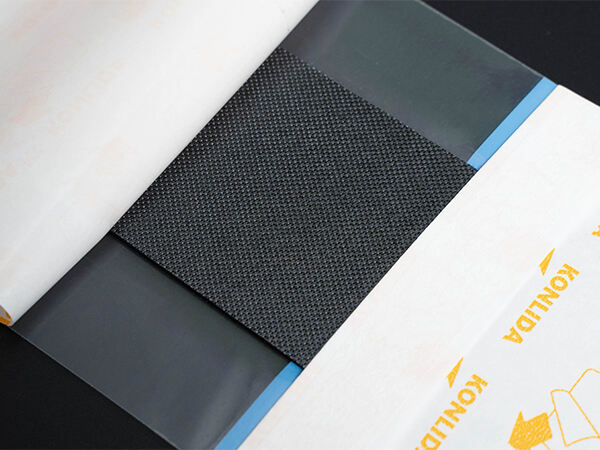

The demand for beauty is increasing as society advances and surgery to reduce scars is now a significant concern hydrocolloid bandages for wounds are always looking for and improving methods to minimize the risk of scarring and trauma in patients while also improving their skills in medicine and decreasing their workload Konlida Medical uses its flexible production and manufacturing capabilities along with its innovative capabilities to create proprietary wound care products Our focus is on treating and taking care of wounds by building strong cooperative relations with hospitals and research institutions We're dedicated to bringing the latest treatments to patients offering a new era of healing and hope

Konlida Medical a high-tech business that integrates engineering medicine and clinical medicine is a high-tech enterprise We provide affordable medical equipment which improve the hydrocolloid bandages for wounds and provide lifesaving treatments for patients Konlida Medical continuously understands customer needs and offers comprehensive customization services We provide product parameter optimization recommendations built on the actual usage needs of our customers This helps them to increase efficiency while reducing costs Our OEM/ODM service is offered to meet the varying requirements of our clients for processing We're dedicated to providing innovative and customer-focused products that enable us to stay on top of the medical field

Konlida Medical's research team is made up of experts in the fields of the clinical sciences, pharmacology, as well as chemical engineering. We employ over 20 engineers as well as RD staff, as well as strong collaborative relationships with universities and hospitals. We own many intellectual property rights that are independent and own numerous patents from national inventors. Konlida Medical conducts regular professional education and educational discussions, focusing on the comprehensive development of both the company as well as its employees. This process enhances the education capabilities of the organization and aims to improve the overall quality of staff. Our operating system continuously assists in the transfer of knowledge to practical applications, thereby hydrocolloid bandages for wounds innovation and excellence within the business.

Equipped with a Class 10,000 cleanroom, a Class 100,000 cleanroom, an Biological Class 10,000 laboratory, physical and chemical labs, as well as a compliant water purification and storage facility that meet the requirements of aseptic, our business is fully prepared for top-quality production. We have over 18 years of experience in the industry, and we use advanced technology for each stage of production. Konlida Medical has passed the hydrocolloid bandages for wounds quality management system certification. It ensures that each step starting from the initial inspection of material to control of production and logistics warehousing, is performed in accordance with industry standards and regulatory requirements. This approach ensures that high-quality medical products are manufactured.

Copyright © Suzhou Konlida Medical Supplies Co., Ltd. All Rights Reserved Privacy Policy